The oil-flooded rotary screw compressor selection guide provides a comprehensive resource for selecting the appropriate compressor for a specific application.

By following the guidelines and recommendations in the selection guide, users can make an informed decision that considers their application’s unique requirements, resulting in a compressor that operates efficiently, reliably, and cost-effectively.

Understanding the Basics of Oil-Flooded Rotary Screw Compressors

1. How do they work?

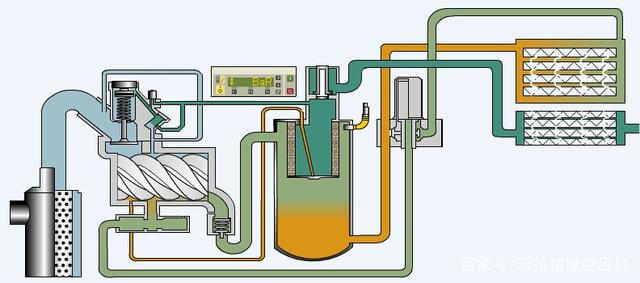

Oil-flooded rotary screw compressors work by using two interlocking rotors that compress air inside a housing. The rotors are typically helical in shape, and as they rotate, the air is drawn into the compressor through the inlet port. As the rotors turn, the air is trapped between the rotors and the housing and is compressed as the volume between the rotors decreases.

Oil is injected into the compressor through a nozzle, which provides a seal between the rotors and the housing, as well as lubricates the rotors and cools the compressed air. As the air/oil mixture exits the compressor element, it enters a separator tank, where the oil is separated from the compressed air. The oil is then recycled back to the inlet side of the compressor element, while the compressed air is discharged through the outlet port.

2. Types of Oil-Flooded Rotary Screw Compressors

A. Single-stage compressors

Single-stage oil-flooded rotary screw compressors use a single stage to compress air and are lubricated with oil to reduce wear and tear on the rotors. They are commonly used in manufacturing and industrial applications where a constant supply of compressed air is required, but may not be suitable for high-pressure or variable flow applications. They are more compact and cost-effective than two-stage compressors and require less maintenance.

B. Two-stage compressors

Two-stage oil-flooded rotary screw compressors use two stages to compress air, resulting in a higher discharge pressure compared to single-stage compressors. The first stage compresses the air to an intermediate pressure, which is then cooled before entering the second stage for further compression to the desired discharge pressure. Two-stage compressors are commonly used in high-pressure applications where a constant supply of compressed air is required. They are typically larger and more expensive than single-stage compressors but can provide higher discharge pressures and variable airflow rates.

C. Variable-speed compressors

Variable-speed oil-flooded rotary screw compressors use a variable-speed drive to adjust the compressor speed to match the air demand. This allows the compressor to operate at the most energy-efficient speed, reducing energy consumption and operating costs. These compressors are particularly effective in applications with variable air demand, where the compressed air requirement changes throughout the day. Variable-speed compressors can also help to reduce the risk of pressure drops and extend the life of the compressor. However, they are generally more expensive than fixed-speed compressors and require more maintenance.

Oil-Flooded Rotary Screw Compressors Advantages and Disadvantages

1. Advantages:

High efficiency: Oil-flooded rotary screw compressors are known for their high efficiency and can deliver high volumes of compressed air with low energy consumption.

Reliability: The simple design of oil-flooded rotary screw compressors means they have fewer moving parts, which reduces the risk of breakdowns and the need for maintenance.

Low noise level: Oil-flooded rotary screw compressors run quietly, making them ideal for use in environments where noise levels need to be kept to a minimum.

High capacity: These compressors can deliver high volumes of compressed air, making them suitable for use in large-scale industrial applications.

2. Disadvantages:

Oil carryover: Oil-flooded rotary screw compressors require oil to operate, which means there is a risk of oil carryover into the compressed air stream. This can be a concern for applications where oil contamination is a problem.

Maintenance: While oil-flooded rotary screw compressors require less maintenance than other types of compressors, they still need regular oil changes, filter replacements, and other routine maintenance tasks to ensure they continue to operate reliably and efficiently.

Initial cost: Oil-flooded rotary screw compressors can be more expensive to purchase than other types of compressors. However, they are generally more efficient, which can result in cost savings over the life of the compressor.

Oil-Flooded Rotary Screw Compressors Applications

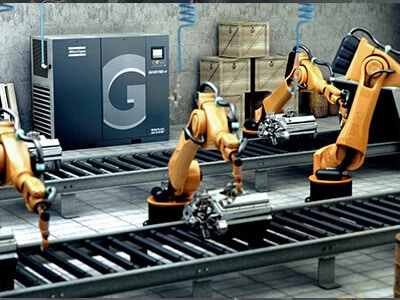

1. Manufacturing: Compressed air is used to power pneumatic tools, machinery, and other equipment in manufacturing facilities.

2. Automotive: Compressed air is used to power paint spraying equipment, pneumatic tools, and air-powered hoists and lifts.

3. Food and beverage: Compressed air is used for packaging, filling, and bottling in the food and beverage industry.

4. Pharmaceuticals: Compressed air is used for manufacturing, filling, and packaging pharmaceutical products.

5. Construction: Compressed air is used to power tools such as jackhammers, drills, and pneumatic nail guns.

6. Mining: Compressed air is used to power drilling equipment, rock drills, and other mining machinery.

7. Energy: Compressed air is used in power generation facilities for pneumatic control systems and for cleaning equipment and components.

Factors to Consider When Selecting an Oil-Flooded Rotary Screw Compressor

A. Capacity and pressure

Capacity and pressure are critical factors to consider as they determine the amount of compressed air that the compressor can deliver and the pressure required for the application. It is important to select a compressor with the appropriate capacity and pressure to ensure that it can meet the demands of the application.

B. Energy efficiency

Energy efficiency is also an important consideration when selecting a compressor. A more energy-efficient compressor can help to reduce operating costs and minimize the impact on the environment. It is essential to consider the compressor’s energy efficiency and select a compressor that delivers optimal performance with minimal energy consumption.

C. Size and weight

Size and weight are also crucial factors to consider, particularly if space is limited. It is important to select a compressor that fits the available space and can be easily transported to the installation site.

D. Noise level

Noise level is another important consideration, especially if the compressor will be operating in a noise-sensitive environment. It is essential to select a compressor that produces minimal noise levels to avoid disrupting the work environment.

E. Maintenance requirements

Maintenance requirements should also be taken into account. Regular maintenance is necessary to keep the compressor operating efficiently and prevent breakdowns. It is essential to select a compressor with manageable maintenance requirements to minimize downtime and maintenance costs.

F. Reliability and durability

Reliability and durability are also critical factors to consider. A reliable and durable compressor can provide a steady supply of compressed air and minimize the risk of breakdowns or the need for costly repairs.

G. Oil-Flooded Rotary Screw Compressor Price

Finally, the cost of the compressor is a crucial consideration. It is important to balance the initial cost of the compressor with its long-term benefits and performance to ensure that it provides the best value for money.

In summary, when selecting an oil-flooded rotary screw compressor, it is essential to consider capacity and pressure, energy efficiency, size and weight, noise level, maintenance requirements, reliability and durability, and cost. Careful consideration of these factors can help to ensure that the compressor meets the application requirements, delivers optimal performance, and provides the best value for money.

Get High-end Oil-Flooded Rotary Screw Compressor

If you are looking for Ingersoll Rand and Atlas Copco Oil-Flooded Rotary Screw Compressor, please do not hesitate to contact us, YScompressor, the trusted Chinese factory of Ingersoll Rand and Atlas air compressors. We offer original products at competitive prices, and we are always here to assist you with your air compression needs.