Ingersoll Rand Air Dryer

The compressed air system creates clean air with lower moisture content by pairing it with an Ingersoll Rand air dryer.

Each Ingersoll Rand desiccant dryer incorporates high-strength desiccant and durable, easily maintained valves for unsurpassed reliability, performance, and customer value.

Heatless and Heated

For Reliability

Desiccant Air Dryers

We have prepared all the air dryer catalogs of Ingersoll Rand here. Leave your email and you will get the PDF immediately.

Ingersoll Rand Compressed Air Dryer

Perfect air-drying solution

- Refrigerated air dryer

- Heatless and heated dryer

- Small or large options

- Advanced environmental sustainability

Model Series

Small-Up Cycling Dryers

Model Series

HL-Heatless Desiccant Dryer

Flow Rate m³/hr

17-255 m³/hr

Flow Rate m³/min

2.5-141.6 m³/min

Operating KW*

0.35-1.25 kw

Pressure Dew Point

Up to -70°C

Model Series

EH-Heated Desiccant Dryer

Model Series

HB-Heated Blower

Flow Rate m³/min

4.2-226.5 m³/min

Flow Rate m³/min

8.9-248.6 m³/min

Pressure Dew Point

Up to -70°C

Pressure Dew Point

Up to -40°C

How do We Ensure the Efficiency of Air Dryers?

Achieve maximum energy savings, while ensuring a continuous supply of dry high-quality air.

Desiccant

All series of Ingersoll Rand Air dryers use high-performance, non-acid desiccants to create the highest performance.

Advanced Control System

The operation panel is simple and intuitive “one button start”. It constantly monitors the functions of the dryer

Dehydration

Ingersoll Rand air dryer can remove 99% of the liquid water in the compressed air with extremely low air loss.

Air Re-Filtration

Ingersoll Rand helps customers obtain nearly 100% water-free pure air through an after-filter system.

High Efficiency Air Dryer for Compressors

Ingersoll Rand’s refrigerated and desiccant air dryer can be used with almost any air compressor.

Economical and Small

Small refrigeration dryer for reciprocating air compressor.

High-End Dryer

Heatless, heated and heated blower desiccant air dryers.

High-Pressure Dryer

High-pressure cycling-refrigerated dryers for PET production.

Modular Dryer

Small-up compact and innovative modular desiccant dryer.

Why Choose Ingersoll Rand Compressed Air Dryer?

Achieve maximum energy savings, while ensuring a continuous supply of dry high-quality air.

- Up to – 70 ℃ pressure dew point.

- Compressed air loss ratio of less than 1%.

- Compatible with almost all types of compressed air systems.

- Ingersoll Rand air dryers use R134a environment-friendly condensate.

- LCX patented technology improves energy efficiency by 18-50%.

- Unpowered design eliminates the need to connect additional power.

A Complete Compressed Air System

The compressed air system of a rotary screw air compressor unit shall include:

Screw Compressor

Rotary screw air compressors are installed in the primary position for compressed air.

Air Receiver Tank

The air tank is commonly used to stabilize pressure and store air. it is indispensable.

Air Dryer

The air dryer is installed behind the air receiver to remove moisture from the compressed air.

Pre-Filter

It is installed between the dryer and the air tank to remove part of the liquid water in advance.

Post-Filter

It is installed behind the air dryer to remove oil and particulate matter from the compressed air.

Air Channel

Air pipes are essential, and high-quality air passages can avoid gas leakage and hazards.

B2B solutions

Those who have cooperated with us for a long time have a profit growth rate of 17% in the first year and 29% in the second year.

Solution

- 10-30% advance payment

- 2-10% order discount

- Market protection, exclusive supply

- Expert monthly training

- Consultant one-to-one service

- Help you increase profits

B2C Solution

- Fastest 3-days delivery

- Support door-to-door delivery

- Factory direct shipment

- OEM compressed air system design

- Package Care-100% risk transfer

- AirCare-extended warranty service

- 7 ×24-hour after-sales support

- On-site maintenance service

Air Dryer Buying Guide

What is the function of the air dryer?

The compressed air system uses an air dryer for two purposes: lowering the temperature of the compressed air and removing moisture in the compressed air.

How do I choose an air dryer?

Selecting the appropriate cold dryer from these key factors: compressed air handling capacity, working pressure, intake air temperature, pressure dew point, ambient temperature, volume weight, and quality.

How long can the air dryer last?

Compressed air dryers can be used for a long time without complicated maintenance

What are the types of air dryers?

Ingersoll Rand has four main types of refrigerated dryers: Refrigerated air dryer, heatless desiccant air dryer, heated desiccant air dryer, heated blower desiccant air dryer.

What is the difference between refrigerated and desiccant dryer?

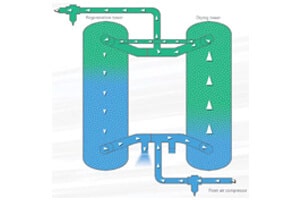

Working principle: Ingersoll Rand desiccant air dryers absorb moisture from compressed air through two adsorption towers filled with desiccant. Refrigerated air dryers use refrigerant to cool the compressed air to a certain dew point and separate the liquid water through a steam-water separator. Dewatering effect: The pressure dew point of the refrigerated dryer is 2-10℃, and the pressure dew point of the desiccant dryer can reach -70℃.