Ingersoll Rand Centrifugal Air Compressor

In the field of centrifugal air compressors, Ingersoll Rand is always your reliable partner.

Ingersoll Rand’s new generation oil-free centrifugal air compressors symbolizes innovation, which enables Centac to become a global leader and benchmark in reliability, efficiency, and productivity even under the worst operating conditions.

Check the MSG Turbo/Centac centrifugal air compressor of Ingersoll Rand here. Leave your email and you will get the PDF immediately.

Ingersoll Rand Centac Air Compressor

Simple but practical design

- High and low pressure

- Multi-stage compressors

- Small size and reduced footprint

- Compressed air volume up to 28000 cfm/min

Model Series

MSG Centac: C400-C3000

Nominal Power

250-4500 kw (350-6000 hp)

Discharge Pressure

1.0-42.1 barg (15-610 psig)

Inlet Flow

40-800 m³/min (1500-28000 cfm)

Compressed Media

Air, oxygen, nitrogen and special gases, etc.

Warranty

Transfer operational risk for up to 10 years

Model Series

MSG Turbo: TA(-NX) 2000-12000

Nominal Power

90-4200kw (125-5650 hp)

Discharge Pressure

2.5-42 barg (35-610 psig)

Inlet Flow

15-525 m³/min (500-18500 cfm)

Compressed Media

Air, oxygen, nitrogen and special gases, etc.

Warranty

Transfer operational risk for up to 10 years

MSG Centac/TURBO-AIR Features and Benefits

Ingersoll Rand has installed more than 41000 centrifugal air compressors around the world with 100% customer satisfaction.

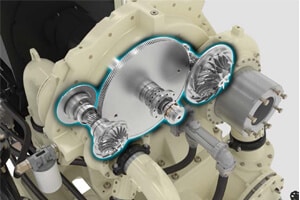

Core Components

High-quality AGMA standard gears have a design life of up to 25 years with a very low operating noise.

No Oil Leakage

The o-shaped plane seals can minimize air and oil leakage to ensure 100% oil-free air.

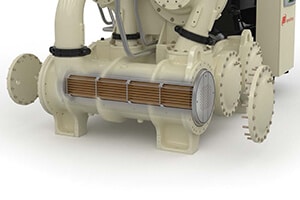

Efficiency

High pressures up to 610psig can be achieved with custom multi-stage compressors.

Easy Maintenance

Through our modular design of centrifugal air compressors, machine maintenance is easier and faster.

Industrial Application of Centrifugal Air Compressor

Ingersoll Rand offers a broad portfolio of reliable centrifugal products that will adapt to your application.

Chemical Industry

Achieve the highest purity to minimize risk of product liability.

Iron Industry

Centrifugal air compressors can provide sufficient compressed air.

Oil & Gas

Robust centrifugal systems that meet API standards.

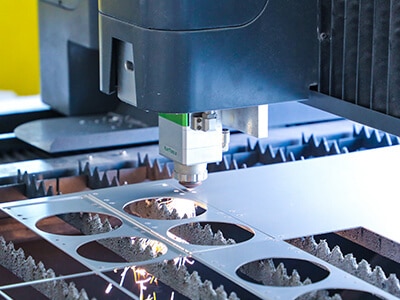

Aerospace

Proven design to meet demanding manufacturing environments.

Why Choose Centrifugal Air Compressor?

If you are looking for reliable centrifugal air compressor , contact us to know more about small or multi-stage compression centrifugal air compressors.

- Cheap and small centrifugal air compressors are available.

- Up to 5-stage compressors are available.

- Compression elements do not wear or require periodic replacement.

- More than 35 years of service life with effective maintenance.

- Essentially vibration-free.

- Engineers around the world are on call to provide on-site service.

Production and Delivery of Orders

We ensure that our work with customers is fast and efficient.

Confirm Order

Our consultants confirm the details of the order with the customer, including general, custom requirements, etc.

Perfect Details

Design solutions for customers and determine the fastest delivery date and packaging of goods, etc.

Production

We send customer order to Ingersoll Rand China factory to start product production.

Daily Updates

Our consultants will proactively update the production process of the machine for the customer.

Final Product

Pre-shipment testing and strict inspection of compressors. Test report available.

Transportation

Wooden case packing and fast delivery, including sea, land, and air transportation.

The CARE Service Program

Provide the highest quality service according to your requirements

PlannedCARE

- Comprehensive parts and service coverage

- Predictable, on-time planned maintenance

- Preventative diagnostics to catch potential problems

- Up to 5-year coverage on major airend components in new centrifugal compressors

PackageCARE

- Total protection, eliminate the risk

- The greatest value for asset management

- Transfer operational risk for up to 10 years

- Includes all scheduled maintenance

- Predictive and analytical tools prevent production interruptions

Buying Guide

What is a centrifugal air compressor?

Centrifugal air compressor unit is an integral gear compressor driven by a motor, single-layer structure, single-stage suction, single-stage exhaust, and providing 100% oil-free compressed air.

What is multi-stage compression?

To meet higher working pressure requirements and compressed gas capacity, can customize 2-stage, 3-stage, and 5-stage centrifugal compressors for customers.

Is there a small and cheap model?

MSG TA(C) 2000 and MSG Centac C400, C700 series with less footprint and affordable price.

what is the working of centrifugal air compressor?

The air enters the impeller of the centrifugal air compressor, the impeller accelerates the air through high-speed rotation, and under the action of centrifugal force, the gas enters the diffuser for pressurization. Repeat the above process continuously until the centrifugal air compressor reaches the required working pressure.

How much does a IR centrifugal compressor cost?

According to customers' needs, the price ranges from $7000 to $200000. Inefficiencies, contaminants, and breakdowns result in costly downtime, product liability, or damage to your brand reputation. centrifugal compressors help eliminate these problems while reducing total lifecycle costs.