Oil Injected Air Compressor

Atlas Copco’s hot-selling, robust, stable, and reliable compressor products – G (A) series oil-injected air compressor.

Atlas Copco’s pace of innovation has never stopped. We always put customers’ needs first and provide you with customized compressed air solutions. Check our oil-injected rotary screw air compressor from this page.

VSD+ 35% Energy Savings

Smart Sensor

Level-1 Energy Efficiency

We have prepared all the oil-injected rotary screw air compressor catalogs of Atlas Copco here. Leave your email and you will get the PDF immediately.

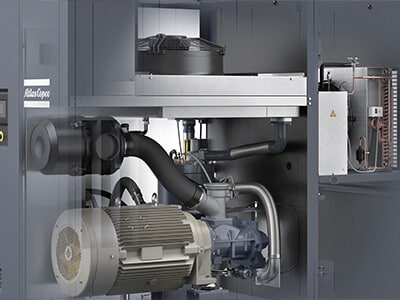

Atlas Copco Oil Injected Screw Compressor

Leading injection technology

- Unique X-type screw air-end

- AGMA13 Manufacturing Standard

- SKF bearing service life up to 150,000 hours

- Bestsellers around the world

Model Series

Atlas Copco GA

Model Series

Atlas Copco G (VSD)

Nominal Power

5.5-550 kw

Nominal Power

4-75 kw / 90-400 kw

Air Capacity (FAD)

0.82-96.8 m³/min

Air Capacity (FAD)

0.47-13.26, 19-81.1 m³/min

Model Series

Atlas Copco GA VSD (+)

Model Series

GA 7-90 VSD iPM

Nominal Power

7-160 kw

Nominal Power

7.5-90 kw

Air Capacity (FAD)

0.4-29.6 m³/min

Air Capacity (FAD)

0.42-18.06 m³/min

Difference of Oil Injected Screw Compressor series

A variety of models are available (ground-mounted, tank-mounted, and full-performance models), enriching customers’ choices.

G (VSD) - Series

The Atlas Copco G-Series(G &G VSD) is an economical and robust oil-injected screw compressor.

GA - Series

The GA series single-stage oil injected screw air compressor uses a super-efficient IE4/IE5 motor.

GA VSD - Series

Advanced variable speed (VSD) technology saves an average of 35% energy compared with fixed speed.

GA VSD+ - Series

GA VSD+can provide more compressed air supply through automatic adjustment of motor speed technology.

Powerful Configuration for Oil-Injected Compressor

State-of-the-art compression elements and many advanced features guarantee robust performance and class-leading efficiency.

Smart Sensor

Real-time monitoring of the operation of each component.

Heavy Duty Filter

It can remove 99% of dust with has a long service life.

Drive System

Efficient gear drive without coupling efficiency loss.

Productivity

Low noise compressor with integrated full built-in design.

Why Choose Atlas Copco Oil-Injected Screw Compressor?

Atlas Copco offers a full range of energy-efficient oil-injected screw compressors to help you further reduce your total energy costs.

- Low noise and vibration.

- Built-in refrigerated air dryer for space saving.

- Simple installation without a separate compressor room.

- Compared with other brands, the air output of Atlas Copco oil injection screw compressors is 0.8-1m3/min higher.

- Spot supplies with seaworthy wooden case packing are available.

- We are always ready to take action to provide customer service globally.

Production and Delivery of Orders

We ensure that our work with customers is fast and efficient.

Confirm Order

Our consultants confirm the details of the order with the customer, including general, custom requirements, etc.

Perfect Details

Design solutions for customers and determine the fastest delivery date and packaging of goods, etc.

Production

We send customer order to Ingersoll Rand China factory to start product production.

Daily Updates

Our consultants will proactively update the production process of the machine for the customer.

Final Product

Pre-shipment testing and strict inspection of compressors. Test report available.

Transportation

Wooden case packing and fast delivery, including sea, land, and air transportation.

B2B solutions

Those who have cooperated with us for a long time have a profit growth rate of 17% in the first year and 29% in the second year.

Solution

- 10-30% advance payment

- 2-10% order discount

- Market protection, exclusive supply

- Expert monthly training

- Consultant one-to-one service

- Help you increase profits

B2C Solution

- Fastest 3-days delivery

- Support door-to-door delivery

- Factory direct shipment

- OEM compressed air system design

- Package Care-100% risk transfer

- AirCare-extended warranty service

- 7 ×24-hour after-sales support

- On-site maintenance service

Oil-Injected Screw Compressor Buying Guide

What is oil injected screw air compressor?

The oil-injected screw air compressor is an oil-cooled air compressor, which lubricates and cools the high-speed rotor with high-quality coolant.

Benefits of oil-injected screw compressor?

They have a good productivity – Atlas Copco G-series oil-injected screw compressor has high energy efficiency, small vibration, small volume and large air volume.

Should I add oil to my air compressor?

The general screw air compressor needs to add new oil every 2000-3000 hours. If you are using a GA 75 VSD oil-injected compressor, replace it every 8000-10000 hours.

What is the price of G-series compressor?

Price is never a problem here. Contact YESHENG immediately to get a favorable quotation.

What is the GA VSD iPM compressor?

Smart drive and intelligent control - the new GA 7-75 VSD iPM oil-cooled permanent magnet variable frequency compressor help you use gas more efficiently, reliably, and energy-efficient, especially for users with fluctuating gas consumption. GA VSD+is combined with the innovative iPM internal permanent magnet motor (IE4) technology. Compared with the GA fixed frequency model, GA VSD+model has a significant energy-saving effect. In addition to energy conservation, GA VSD+also increases the air displacement (FAD) compared with the GA fixed frequency model.