What is A Rotary Screw Air Compressors

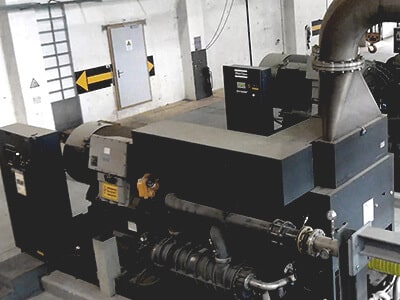

Oil-flooded rotary screw compressors are a type of positive displacement compressor that uses two rotors to compress air. The rotors are shaped like screws and are driven by a motor. As the rotors turn, the air is drawn into the compressor and trapped between the rotors, where it is compressed and then discharged. Oil is injected into the compressor to lubricate the rotors, cool the compressed air, and seal any gaps between the rotors and the housing. The oil is then separated from the compressed air and recycled within the compressor. Oil-flooded rotary screw compressors are widely used in industrial applications for their high efficiency, reliability, and low noise levels.

IR Oil-Flooded Screw Air Compressors Key Components

Oil-flooded rotary screw compressors have several key components that work together to compress air and deliver it to the application. The main components of an oil-flooded rotary screw compressor include:

1. Compressor element: The compressor element consists of two interlocking rotors that compress air as they turn.

2. Inlet filter: The inlet filter is located at the air inlet port and removes contaminants from the incoming air.

3. Oil filter: The oil filter removes contaminants from the oil that is used to lubricate and cool the compressor.

4. Oil cooler: The oil cooler lowers the temperature of the oil before it enters the compressor element.

5. Separator tank: The separator tank separates oil from the compressed air after it exits the compressor element.

6. Aftercooler: The aftercooler lowers the temperature of the compressed air before it exits the compressor, reducing the moisture content and preventing damage to downstream equipment.

7. Air receiver tank: The air receiver tank stores compressed air and provide a steady supply of air to the application.

8. Control system: The control system monitors and controls the compressor’s operation, regulating the air pressure, temperature, and oil level.

These components work together to ensure the efficient, reliable, and safe operation of the oil-flooded rotary screw compressor. Regular maintenance and replacement of components are essential to ensure the compressor continues to operate optimally.

The importance of routine maintenance of oil-flooded rotary screw air compressor

Routine maintenance of oil-flooded rotary screw air compressors is essential to ensure optimal performance, prolong the compressor’s lifespan, and prevent costly breakdowns. Regular maintenance can also help identify potential issues before they become significant problems.

Some benefits of routine maintenance of oil-flooded rotary screw air compressors include:

1. Increased energy efficiency: Regular maintenance can help ensure that the compressor is operating at peak efficiency, reducing energy consumption and operating costs.

2. Improved air quality: Regular maintenance can help ensure that the compressor is producing high-quality air, reducing the risk of contamination and product spoilage.

3. Prolonged lifespan: Regular maintenance can help prevent wear and tear on the compressor’s components, prolonging the compressor’s lifespan.

4. Reduced downtime: Regular maintenance can help prevent breakdowns and reduce the risk of unplanned downtime.

5. Safety: Regular maintenance can help ensure that the compressor is operating safely and reduce the risk of accidents or injuries.

Routine maintenance for oil-flooded rotary screw compressors typically includes regular oil and filter changes, cleaning and inspecting the compressor’s internal components, and checking for any leaks or unusual vibrations, or noises.

It is recommended to consult the manufacturer’s guidelines for specific maintenance schedules and procedures and to have a qualified technician perform any maintenance or repairs.

Ingersoll Rand Oil-Flooded Screw Air Compressors Routine maintenance

1. Regular oil changes: The compressor oil should be changed on a regular basis to ensure proper lubrication and cooling of the compressor.

2. Air filter replacement: The air filter should be replaced periodically to prevent dust and other contaminants from entering the compressor and damaging the internal components.

3. Cooling system maintenance: The cooling system should be checked and cleaned regularly to prevent overheating and ensure efficient cooling of the compressor.

4. Belt and pulley inspection: The belts and pulleys that drive the compressor should be checked periodically for wear and tension.

5. Valve maintenance: The compressor valves should be inspected and cleaned on a regular basis to prevent leaks and ensure efficient operation.

6. System leak detection: The compressed air system should be checked for leaks on a regular basis to prevent energy loss and reduce operating costs.

7. Electrical system maintenance: The electrical components of the compressor, including wiring and controls, should be inspected and maintained as needed to ensure safe and efficient operation.

Ingersoll Rand Rotary Screw Air Compressors Common issues and their solutions

1. High discharge temperature: This can be caused by a dirty air filter, inadequate cooling, or a malfunctioning thermostat. To address this issue, check the air filter and clean or replace it as needed. Check the cooling system and ensure that it is functioning properly. If the thermostat is malfunctioning, it may need to be replaced.

2. Excessive oil carryover: This can be caused by a dirty separator, excessive oil level, or a malfunctioning scavenge line. To fix this issue, clean or replace the separator element, adjust the oil level to the correct level, and check the scavenge line for proper function.

3. Unusual noises: This can be caused by loose or worn components, low oil pressure, or excessive vibration. To address this issue, tighten any loose components or replace any worn parts. Check the oil pressure and add oil as needed. Inspect the vibration dampeners and adjust or replace them as needed.

4. System leaks: This can be caused by damaged or worn components, loose fittings, or worn gaskets. To address this issue, inspect the system for leaks and replace any damaged or worn components. Tighten any loose fittings and replace any worn gaskets.

5. Electrical issues: This can be caused by a malfunctioning motor, damaged wiring, or a faulty control panel. To fix this issue, consult a qualified technician to diagnose and repair any electrical issues.

IR Screw Air Compressors Signs of potential problems

1. Increased energy consumption: If the compressor is consuming more energy than usual, it may be a sign of an issue such as an air leak, dirty filters, or excessive oil carryover.

2. Unusual noises: Strange or unusual noises, such as knocking or rattling, can indicate a problem with the compressor’s internal components.

3. High discharge temperature: If the discharge temperature is higher than normal, it may indicate an issue with the cooling system or a malfunctioning thermostat.

4. Excessive oil carryover: If there is an excessive amount of oil in the compressed air system, it may indicate an issue with the separator element, oil level, or scavenge line.

5. Poor air quality: If the compressed air system is producing poor-quality air, it may indicate a problem with the filters, dryers, or other components.

6. Vibrations or excessive movement: If the compressor is vibrating excessively or moving, it may indicate a problem with the mounting or vibration dampeners.

7. Electrical issues: If the compressor is having issues starting, or if the control panel is malfunctioning, it may indicate an issue with the electrical system.

As an authorized Ingersoll Rand distributor, Ys compressor is committed to providing a competitive range of Ingersoll Rand air compressors and Atlas compressors to customers around the world.

Contact us for competitively priced Ingersoll Rand products.