Atlas Copco Centrifugal Compressor

Atlas Copco centrifugal compressors are industrial oil-free air compressors tailored for you with 1-13 bar working pressure.

Atlas Copco ZH series centrifugal compressors – Advanced turbine technology and unique impeller provide the best combination of high flow and low energy consumption. Learn more about how we improve your air quality from this page.

Eliminated Blow-Off

Container design

Optimize System

We have prepared all the centrifugal air compressor catalogs of Atlas Copco here. Leave your email and you will get the PDF immediately.

Atlas Copco Centrifugal Compressor

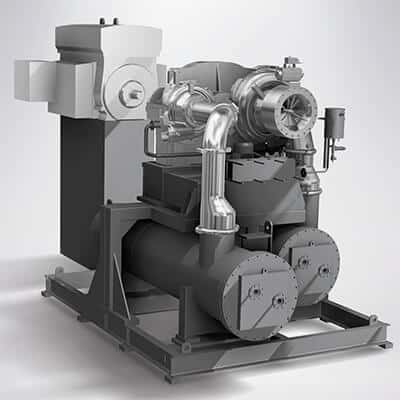

ZH/ZH+/ZHL Customizable

- AGMA Class A4 gears

- 0% oil content of compressed air

- A very compact containerized integrated design

- Installed mounted cooling water manifold

Model Series

Atlas Copco ZH/ZH+/ZHL

Nominal Power

355 kw – 3,150 kw

Power HP

500-4350 hp

Air Capacity (FAD)

76.32 m³/min – 587.4 m³/min

Working Pressure

1 bar(e) – 13 bar(e)

Compression

Single or multi-stage compression

Model Series

Atlas Copco ZH/ZH+/ZHL

Nominal Power

355 kw – 3,150 kw

Capacity FAD l/s

1,272 gal/min – 9,790 gal/min

Air Capacity (FAD)

2,696 cfm – 20,744 cfm/min

Fixed Speed Type

14.5 psig – 190 psig

Compression

Single or multi-stage compression

Advantages of Atlas Copco Centrifugal Compressor

Atlas Copco provides you with mature centrifugal power solutions.

Container Design

Container-integrated design helps factories minimize the footprint of centrifugal air compressors.

Separate Components

Modular components make maintenance and overhaul of centrifugal air compressors more convenient.

Advanced Technique

Rear-end impeller design with higher operational flexibility, adjustable range up to 35%.

Strict Production

The ZH series centrifugal compressors are designed and processed strictly according to ISO 22000, and ISO 9001.

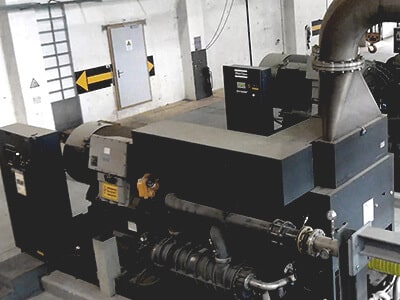

Project of Atlas Copco Centrifugal Compressor

Atlas Copco centrifugal compressor has been applied to many important projects in many countries around the world.

Swiss Chemical Group

ZH15000 centrifugal compressor – 10% energy saving and 75% water consumption reduction.

China Wanshan Food

2.5 bar, 114000 m3/h – Atlas centrifugal compressor helps the food fermentation industry.

Portugal H2O2 Factory

Atlas Copco completed the ZH compressor overhaul project in 9 days – originally 28 days.

American Royole TECH

Several ZH+ series centrifugal compressors are installed in Royole’s production plant.

Why Choose Atlas Copco Centrifugal Compressor?

Use an Atlas Copco centrifugal compressor to maximize energy efficiency and eliminate all operational risks.

- Millions of hours of trouble-free operation.

- 60 years of experience in centrifuge production.

- Fault-free installation, easy commissioning and quick start-up.

- ZH series centrifuges achieve higher flow with lower energy usage.

- It can be upgraded based on the original machine according to customer needs.

Production and Delivery of Orders

Usually, the production period of the centrifugal compressor takes half a year or more, but Atlas Copco China can deliver it faster for you.

Confirm Order

Our consultants confirm the details of the order with the customer, including general, custom requirements, etc.

Perfect Details

Design solutions for customers and determine the fastest delivery date and packaging of goods, etc.

Production

We send customer order to Ingersoll Rand China factory to start product production.

Daily Updates

Our consultants will proactively update the production process of the machine for the customer.

Final Product

Pre-shipment testing and strict inspection of compressors. Test report available.

Transportation

Wooden case packing and fast delivery, including sea, land, and air transportation.

Technologies & Solutions

Choose a centrifugal air compressor manufacturer you can trust – Atlas Copco China

Features

- ZH/ZH+/ZHL Series

- Core compressor

- Energy-saving inlet guide vanes

- Easily accessible gearbox

- AGMA Class A4 gears

- High-efficiency stainless steel intercoolers and after-coolers

- Controller for maximum reliability

Solution

- Faster delivery than other manufacturers

- Efficient inlet silencer and filter

- Integrated blow-off valve and silencer

- Mounted cooling water manifold

- Noise attenuating canopy

- 7 ×24-hour after-sales support

Atlas Copco Centrifugal Compressor Buying Guide

Where are centrifugal compressors produced?

Made by Atlas Copco China Factory. Contact YESHENG to buy high-quality Atlas Copco centrifugal compressors at cheaper prices.

What the differences between ZH and ZHL?

They are all Atlas Copco integrally geared compressors. ZHL is a single-stage compression centrifugal compressor, and ZH is a two-stage or multi-stage centrifugal compressor.

How soon can I receive the goods?

If the compressor is not specially customized, it is usually completed within 4-8 weeks.

How to choose a centrfugal compressor?

Atlas Copco centrifugal compressors are suitable for industrial production with high air purity and air volume requirements. When you decide to purchase a centrifugal air compressor, you should consider the compressed air capacity (FAD), working pressure, price, installation, and service.

Range of Atlas Copco centrifugal air compressors

Atlas Copco centrifugfal compressors series include: ZH+ & ZH 355-900 (355-900 kW/500-1200 hp), ZH+ & ZH 630-1600 (630-1600 kW/900-2250 hp) , ZH 1000-3150 (1000-3150 kW/1400-4350 hp), and ZHL 7-8 Single stage ccentrifugal air compressor.