Máy nén khí phun dầu

Các sản phẩm máy nén bán chạy, mạnh mẽ, ổn định và đáng tin cậy của Atlas Copco – Máy nén khí phun dầu dòng G (A).

Tốc độ đổi mới của Atlas Copco chưa bao giờ dừng lại. Chúng tôi luôn đặt nhu cầu của khách hàng lên hàng đầu và cung cấp cho bạn các giải pháp khí nén tùy chỉnh. Kiểm tra máy nén khí trục vít phun dầu của chúng tôi từ trang này.

VSD+ Tiết kiệm năng lượng 35%

Cảm biến thông minh

Hiệu quả năng lượng cấp 1

Chúng tôi đã chuẩn bị tất cả các danh mục máy nén khí trục vít phun dầu của Atlas Copco tại đây. Để lại email của bạn và bạn sẽ nhận được bản PDF ngay lập tức.

Máy nén khí trục vít phun dầu Atlas Copco

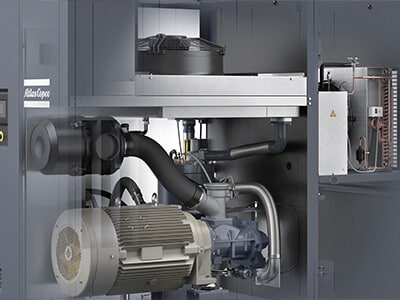

Công nghệ phun hàng đầu

- Đầu vít loại X độc đáo

- Tiêu chuẩn sản xuất AGMA13

- Tuổi thọ vòng bi SKF lên tới 150.000 giờ

- Sách bán chạy nhất trên toàn thế giới

Dòng mô hình

Atlas Copco GA

Dòng mô hình

Atlas Copco G (VSD)

Quyền lực danh nghĩa

5,5-550 kw

Quyền lực danh nghĩa

4-75kw / 90-400kw

Công suất không khí (FAD)

00,82-96,8 m³/phút

Công suất không khí (FAD)

00,47-13,26, 19-81,1 m³/phút

Dòng mô hình

Atlas Copco GA VSD (+)

Dòng mô hình

GA 7-90 VSD iPM

Quyền lực danh nghĩa

7-160kw

Quyền lực danh nghĩa

7,5-90 kw

Công suất không khí (FAD)

00,4-29,6 m³/phút

Công suất không khí (FAD)

00,42-18,06 m³/phút

Sự khác biệt của dòng máy nén trục vít phun dầu

Có sẵn nhiều mẫu mã đa dạng (mô hình gắn trên mặt đất, mô hình gắn trên xe tăng và mô hình hiệu suất đầy đủ), làm phong phú thêm sự lựa chọn của khách hàng.

G (VSD) - Chuỗi

Atlas Copco G-Series(G &G VSD) là máy nén khí trục vít phun dầu mạnh mẽ và tiết kiệm.

GA - Dòng sản phẩm

Máy nén khí trục vít phun dầu một tầng dòng GA sử dụng động cơ IE4/IE5 siêu hiệu quả.

GA VSD - Dòng sản phẩm

Công nghệ tốc độ biến thiên (VSD) tiên tiến giúp tiết kiệm trung bình 35% năng lượng so với tốc độ cố định.

GA VSD+ - Dòng

GA VSD+ có thể cung cấp nhiều khí nén hơn thông qua việc tự động điều chỉnh công nghệ tốc độ động cơ.

Cấu hình mạnh mẽ cho máy nén khí phun dầu

Các phần tử nén tiên tiến nhất và nhiều tính năng tiên tiến đảm bảo hiệu suất mạnh mẽ và hiệu quả hàng đầu.

Cảm biến thông minh

Giám sát thời gian thực hoạt động của từng thành phần.

Bộ lọc hạng nặng

Nó có thể loại bỏ 99% bụi và có tuổi thọ cao.

Hệ thống truyền động

Truyền động bánh răng hiệu quả mà không làm giảm hiệu suất khớp nối.

Năng suất

Máy nén tiếng ồn thấp với thiết kế tích hợp đầy đủ.

Tại sao nên chọn Máy nén khí trục vít phun dầu Atlas Copco?

Atlas Copco cung cấp đầy đủ các loại máy nén trục vít phun dầu tiết kiệm năng lượng để giúp bạn giảm hơn nữa tổng chi phí năng lượng.

- Tiếng ồn và độ rung thấp.

- Máy sấy không khí lạnh tích hợp để tiết kiệm không gian.

- Lắp đặt đơn giản không cần phòng máy nén riêng.

- So với các hãng khác, sản lượng khí của máy nén khí trục vít phun dầu Atlas Copco cao hơn 0,8-1m3/phút.

- Nguồn cung cấp tại chỗ với bao bì bằng gỗ có thể đi biển đều có sẵn.

- Chúng tôi luôn sẵn sàng hành động để cung cấp dịch vụ khách hàng trên toàn cầu.

Sản xuất và giao đơn đặt hàng

Chúng tôi đảm bảo rằng công việc của chúng tôi với khách hàng diễn ra nhanh chóng và hiệu quả.

Xác nhận đơn hàng

Các chuyên gia tư vấn của chúng tôi xác nhận các chi tiết của đơn đặt hàng với khách hàng, bao gồm các yêu cầu chung, yêu cầu tùy chỉnh, v.v.

Chi tiết hoàn hảo

Thiết kế giải pháp cho khách hàng và xác định ngày giao hàng, đóng gói hàng hóa nhanh nhất, v.v.

Sản xuất

Chúng tôi gửi đơn đặt hàng của khách hàng đến nhà máy Ingersoll Rand Trung Quốc để bắt đầu sản xuất sản phẩm.

Cập nhật hàng ngày

Đội ngũ tư vấn của chúng tôi sẽ chủ động cập nhật quy trình sản xuất của máy cho khách hàng.

Sản phẩm cuối cùng

Kiểm tra trước khi giao hàng và kiểm tra nghiêm ngặt máy nén. Báo cáo thử nghiệm có sẵn.

Vận tải

Đóng gói vỏ gỗ và giao hàng nhanh, bao gồm vận chuyển đường biển, đường bộ và đường hàng không.

Giải pháp B2B

Những người hợp tác lâu dài với chúng tôi có tốc độ tăng trưởng lợi nhuận là 17% trong năm đầu tiên và 29% trong năm thứ hai.

Giải pháp

- Trả trước 10-30%

- Giảm giá đơn hàng 2-10%

- Bảo vệ thị trường, cung cấp độc quyền

- Đào tạo chuyên môn hàng tháng

- Dịch vụ tư vấn một-một

- Giúp bạn tăng lợi nhuận

Giải pháp B2C

- Giao hàng nhanh nhất trong 3 ngày

- Hỗ trợ giao hàng tận nơi

- Nhà máy giao hàng trực tiếp

- Thiết kế hệ thống khí nén OEM

- Chăm sóc trọn gói - Chuyển giao rủi ro 100%

- Dịch vụ bảo hành mở rộng AirCare

- Hỗ trợ sau bán hàng 7 × 24 giờ

- Dịch vụ bảo trì tận nơi

Hướng dẫn mua máy nén khí trục vít phun dầu

Máy nén khí trục vít phun dầu là gì?

Máy nén khí trục vít phun dầu là máy nén khí làm mát bằng dầu, có tác dụng bôi trơn và làm mát rôto tốc độ cao bằng chất làm mát chất lượng cao.

Lợi ích của máy nén khí trục vít phun dầu?

Chúng có năng suất tốt – Máy nén trục vít phun dầu dòng G của Atlas Copco có hiệu suất năng lượng cao, độ rung nhỏ, thể tích nhỏ và thể tích không khí lớn.

Tôi có nên thêm dầu vào máy nén khí của mình không?

Máy nén khí trục vít thông thường cần bổ sung dầu mới sau mỗi 2000-3000 giờ. Nếu bạn đang sử dụng máy nén phun dầu GA 75 VSD, hãy thay thế nó sau mỗi 8000-10000 giờ.

Giá máy nén G-series là bao nhiêu?

Giá cả không bao giờ là vấn đề ở đây. Hãy liên hệ ngay với YESHENG để nhận được báo giá ưu đãi.

Máy nén GA VSD iPM là gì?

Ổ đĩa thông minh và điều khiển thông minh - máy nén tần số biến thiên nam châm vĩnh cửu làm mát bằng dầu GA 7-75 VSD iPM mới giúp bạn sử dụng gas hiệu quả hơn, đáng tin cậy hơn và tiết kiệm năng lượng hơn, đặc biệt đối với người dùng có mức tiêu thụ gas dao động. GA VSD+ được kết hợp với công nghệ động cơ nam châm vĩnh cửu bên trong iPM (IE4) cải tiến. So với mô hình tần số cố định GA, mô hình GA VSD+ có hiệu quả tiết kiệm năng lượng đáng kể. Ngoài việc bảo toàn năng lượng, GA VSD+ còn tăng độ dịch chuyển không khí (FAD) so với mô hình tần số cố định GA.