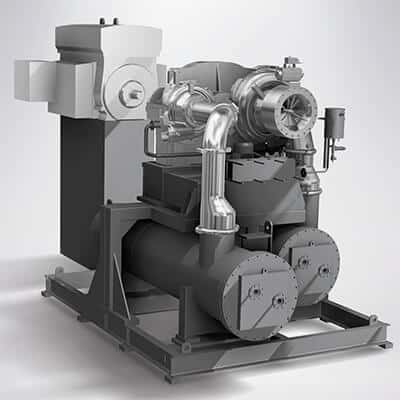

아트라스 콥코 원심 압축기

아트라스콥코 원심 압축기는 작동 압력이 1~13bar인 산업용 오일 프리 공기 압축기입니다.

Atlas Copco ZH 시리즈 원심 압축기 – 고급 터빈 기술과 고유한 임펠러는 고유량과 낮은 에너지 소비의 최상의 조합을 제공합니다. 이 페이지에서 공기질을 개선하는 방법에 대해 자세히 알아보세요.

블로우오프 제거

컨테이너 디자인

시스템 최적화

아트라스콥코의 모든 원심 공기 압축기 카탈로그를 여기에 준비했습니다. 이메일을 남겨주시면 즉시 PDF를 받으실 수 있습니다.

아트라스 콥코 원심 압축기

모델 시리즈

아트라스 콥코 ZH/ZH+/ZHL

공칭 전력

355킬로와트 – 3,150킬로와트

파워 HP

500-4350마력

공기 용량(FAD)

76.32m³/분 – 587.4m³/분

작동 압력

1바 – 13바

압축

단일 또는 다단계 압축

모델 시리즈

아트라스 콥코 ZH/ZH+/ZHL

공칭 전력

355킬로와트 – 3,150킬로와트

용량 FAD l/s

1.272갤런/분 - 9.790갤런/분

공기 용량(FAD)

2,696cfm – 20,744cfm/분

정속형

14.5psig ~ 190psig

압축

단일 또는 다단계 압축

아트라스콥코 원심 압축기의 장점

Atlas Copco는 성숙한 원심력 솔루션을 제공합니다.

컨테이너 디자인

컨테이너 통합 설계는 공장에서 원심 공기 압축기의 설치 공간을 최소화하는 데 도움이 됩니다.

별도의 구성 요소

모듈식 구성 요소는 원심 공기 압축기의 유지 관리 및 정밀 검사를 더욱 편리하게 만듭니다.

고급 기술

더 높은 작동 유연성과 최대 35%의 조정 범위를 갖춘 후방 임펠러 설계.

엄격한 생산

ZH 시리즈 원심 압축기는 ISO 22000 및 ISO 9001에 따라 엄격하게 설계 및 처리되었습니다.

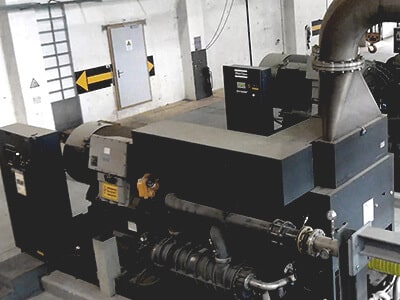

Atlas Copco 원심 압축기 프로젝트

Atlas Copco 원심 압축기는 전 세계 여러 국가의 많은 중요한 프로젝트에 적용되었습니다.

스위스 화학 그룹

ZH15000 원심 압축기 – 에너지 10% 절약, 물 소비량 75% 감소.

중국완산식품

2.5bar, 114000m3/h – Atlas 원심 압축기는 식품 발효 산업을 돕습니다.

포르투갈 H2O2 공장

Atlas Copco는 원래 28일이었던 ZH 압축기 정밀 검사 프로젝트를 9일 만에 완료했습니다.

아메리칸 로욜 테크

Royole의 생산 공장에는 여러 ZH+ 시리즈 원심 압축기가 설치되어 있습니다.

Atlas Copco 원심 압축기를 선택하는 이유는 무엇입니까?

Atlas Copco 원심 압축기를 사용하여 에너지 효율성을 극대화하고 모든 운영 위험을 제거하십시오.

- 수백만 시간 동안 문제 없이 작동합니다.

- 원심분리기 생산 분야에서 60년의 경험을 쌓았습니다.

- 오류 없는 설치, 손쉬운 시운전 및 빠른 시동.

- ZH 시리즈 원심분리기는 더 낮은 에너지 사용량으로 더 높은 유량을 달성합니다.

- 고객 요구에 따라 원래 기계를 기반으로 업그레이드할 수 있습니다.

주문 생산 및 배송

일반적으로 원심 압축기의 생산 기간은 반년 이상이 소요되지만 아트라스콥코 중국에서는 더 빨리 납품할 수 있습니다.

주문 확인

당사 컨설턴트는 일반 요구 사항, 맞춤형 요구 사항 등을 포함하여 고객과 함께 주문 세부 사항을 확인합니다.

완벽한 디테일

고객을 위한 솔루션을 설계하고 가장 빠른 배송 날짜와 상품 포장 등을 결정합니다.

생산

제품 생산을 시작하기 위해 고객 주문을 Ingersoll Rand 중국 공장으로 보냅니다.

일일 업데이트

우리 컨설턴트는 고객을 위해 기계 생산 프로세스를 적극적으로 업데이트합니다.

최종 제품

선적 전 테스트 및 압축기에 대한 엄격한 검사. 테스트 보고서를 사용할 수 있습니다.

운송

해상, 육상 및 항공 운송을 포함한 목재 케이스 포장 및 빠른 배송.

기술 및 솔루션

신뢰할 수 있는 원심 공기 압축기 제조업체를 선택하세요 – Atlas Copco 중국

특징

- ZH/ZH+/ZHL 시리즈

- 코어 압축기

- 에너지 절약형 입구 가이드 베인

- 쉽게 접근할 수 있는 기어박스

- AGMA 클래스 A4 기어

- 고효율 스테인리스강 인터쿨러 및 애프터쿨러

- 최대의 신뢰성을 위한 컨트롤러

Atlas Copco 원심 압축기 구매 가이드

원심 압축기는 어디에서 생산됩니까?

아트라스콥코 중국 공장에서 제작되었습니다. 고품질 Atlas Copco 원심 압축기를 저렴한 가격에 구매하려면 YESHENG에 문의하세요.

ZH와 ZHL의 차이점은 무엇입니까?

이들은 모두 Atlas Copco의 일체형 기어 압축기입니다. ZHL은 단일 단계 압축 원심 압축기이고 ZH는 2단계 또는 다단계 원심 압축기입니다.

얼마나 빨리 상품을 받을 수 있나요?

압축기를 특별히 맞춤 제작하지 않은 경우 일반적으로 4~8주 내에 완료됩니다.

원심 압축기를 선택하는 방법은 무엇입니까?

아트라스콥코 원심 압축기는 공기 순도와 공기량 요구 사항이 높은 산업 생산에 적합합니다. 원심 공기 압축기를 구매하기로 결정했다면 압축 공기 용량(FAD), 작동 압력, 가격, 설치 및 서비스를 고려해야 합니다.

Atlas Copco 원심 공기 압축기 제품군

Atlas Copco centrifugfal compressors series include: ZH+ & ZH 355-900 (355-900 kW/500-1200 hp), ZH+ & ZH 630-1600 (630-1600 kW/900-2250 hp) , ZH 1000-3150 (1000-3150 kW/1400-4350 hp), and ZHL 7-8 Single stage ccentrifugal air compressor.